Game-changing innovation enables salt-free dyeing of cellulose with transformative environmental & cost benefits

This technology reduces the devastating environmental impact of cellulose dyeing & marks a bold step towards a more sustainable future of the textile industry.

We do not shy away from major challenges. The fact that no one, not even global chemical players, have yet managed to solve this problem was never a reason to give up.”

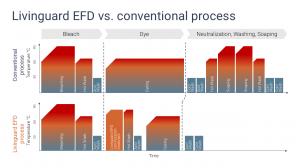

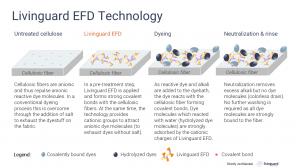

PFAEFFIKON SZ, SZ, SWITZERLAND, August 14, 2025 /EINPresswire.com/ -- Livinguard Technologies AG has developed Livinguard EFD (Economically & Environmentally Friendly Dyeing) - a breakthrough new approach to cellulose dyeing. The Livinguard system involves a cationization pretreatment to enable completely salt-free dyeing with an almost complete exhaustion of the dyestuff on the fabric. Thus, the solution reduces required effluent treatments to recover salt and completely eradicates all washing & soaping steps after dyeing (and associated discharge of hydrolyzed dyes in the effluent) which is required in a conventional process to remove unfixed dyes. The Livinguard EFD system is compatible with existing equipment and can therefore be adopted without any capital expenditure for processing mills. — Sanjeev Swamy, CEO of Livinguard Technologies AG

Livinguard's solution promises a disruptive sustainability and cost impact for mills with up to 50% water savings and up to 50% energy & CO2 savings while providing up to 40% increase in productivity and full compatibility with established equipment. Furthermore, the technology allows for the partial or complete substitution of other chemical additives such as soaping agents, lower dosing of dyestuffs due to better exhaustion and higher production up-time even during water shortages. Based on initial calculations and estimates, the adoption of the Livinguard EFD technology has the potential to decrease the total cost per processed volume by up to 20% while increasing production capacity on existing equipment by up to 30%.

The innivative technology is currently extensively validated and tested for robustness at commercial scale with various early adopters and industry partners worldwide. The commercial launch of the solution is planned for Q4 2025.

Current textile dyeing practices contribute significantly to the apparel industry's poor environmental track record due to their excessive use of water, energy, and the associated pollution from discharging toxic chemicals in the effluent. At the same time, processing mills face economic challenges due to price pressure driven by intensifying global competition, ballooning costs due to inflation and high energy prices – all while facing increasing environmental scrutiny from brands and regulators.

Cationic dyeing - the basic concept for this innovative technology from Livinguard - was first described in the 1930s and is therefore not new. The Livinguard EFD process, approach and objectives overall resemble past attempts from major players in the industry to enable salt-free dyeing with a pre-cationization treatment. However, these products were not widely adopted as they were either not economically viable for the dyeing plants (too expensive), did not meet the performance specifications in terms of color fastness or dyeing quality, or were too complex and cumbersome to use in practice. Based on available test results so far, Livinguard Technologies believes that these shortcomings have been adequately addressed, and thus a technical breakthrough has been achieved. The Livinguard EFD technology leverages a cationic molecule that provides significantly higher efficiency, allows for a wet-on-wet process (meaning it does not require interim drying of the fabric before dyeing) and is priced to not only deliver a positive environmental impact, but also a tangible economic benefit to the dyeing houses.

This breakthrough is the result of a long development journey with deep global collaboration. The teams at Livinguard have screened over the course of 15 years over 200 potentially suitable molecules and ultimately developed a proprietary chemistry. The technology has been extensively tested for performance, safety and environmental impact, commercial viability and finally compliance with the highest industry safety standards.

Increasing attention has been brought to the numerous negative environmental impacts that the apparel industry is responsible for. Dyeing of cellulose fabrics consumes up to 125L of fresh water per kg of treated material. 10-15% of dyes ultimately end up in the released wastewater and disturb aquatic life. Many hundred tonnes of dangerous chemicals from dyeing are released into the wastewater every year and over 20% of the world’s water pollution can be attributed to the fashion and textile industry. It is estimated that about 200,000 tons of dyes (worth 1 billion USD) are wasted and washed out in the effluent due to inefficient dyeing and finishing processes. Furthermore, energy use and resulting carbon emissions of the fashion sector are substantial. The industry accounts for 2-8% of global carbon emissions driven by energy-intense manufacturing processes and transportation in globalized supply chains.

Shifting the entire addressable global production of around 7 million tonnes of processed and dyed cellulose annually to the Livinguard EFD solution could have a transformative environmental impact. Based on initial estimates, the Livinguard EFD technology could save up to 190 billion liters (about 52 billion gallons) of freshwater and up to 7 million tons of CO2 annually. Other sustainability benefits such as additional greenhouse gas savings from production, transportation and discarding/ insinuation of salt, dyestuffs and other chemistries have not yet been considered in these estimates.

News Department

Livinguard Technologies AG

news@livinguard.com

Visit us on social media:

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.